Layers Cage for Sale in Nigeria Egg Laying Cages

Product Details

Type: A/H type layer chicken cage

Material: Hot dipped galvanized, Q235

Tiers: 3/4 Tiers

Chicken quantity: 2000-20000/House

Life time: 20 Years

Certification: ISO 9001,SONCAP,PVOC

Feeding trough: PVC

Water pipe thickness: 2mm

A Type Layer Cages VS H Type Layer Cages

A type layer chicken cages and H type layer chicken cages are both commonly used in poultry farming for housing and managing layers (egg-laying chickens). Here are some key differences between the two types of cages:

1. Design:

- A type layer chicken cage: A type cages have a sloped roof and the cages are arranged in a vertical stack, resembling the letter “A”.

- H type layer chicken cage: H type cages have a flat roof and the cages are arranged in a horizontal row, resembling the letter “H”.

2. Space utilization:

- A type layer chicken cage: A type cages are more space-efficient as they allow for vertical stacking, making them suitable for farms with limited space.

- H type layer chicken cage: H type cages require more floor space as they are arranged in a horizontal row, making them suitable for larger farms with more available space.

3. Feeding, watering system and egg collecting machine

Feeding system

Watering system

Egg collecting machine

- A type and H type layer chicken cages can both be equipped with automated feeding, watering system and egg collecting machine to ensure efficient feeding, watering and egg collecting of the chickens.

4. Cost:

- The cost of A type and H type layer chicken cages may vary depending on the design, materials used, and the size of the cages. Generally, A type cages may be more cost-effective for smaller farms with limited space, while H type cages may be more suitable for larger farms.

Ultimately, the choice between A type and H type layer chicken cages will depend on factors such as the size of the farm, available space, budget, and specific requirements of the poultry operation. Contact us now to get the best advice.

Layer Chicken Cage Specification

| Model | Overall size (L x W x H) | Nest per strip | Total nests (doors) | Size of the nest | Chickens/nest | Capacity (Birds/Set) |

| A-96 (Hot sale) | 1.88 x 2.1 x 1.95 m | 4 | 24 | 0.47 x 0.35 x 0.37 x 0.32 m | 4 | 96 |

| A-160 (Hot sale) | 2.15 x 2.4 x 1.95 m | 5 | 40 | 0.43 x 0.38 x 0.38 x 0.33 m | 4 | 160 |

| A-120 | 2.15 x 2.1 x 1.95 m | 5 | 40 | 0.47 x 0.35 x 0.37 x 0.33 m | 3 | 120 |

| A-128 | 1.88 x 2.4 x 1.95 m | 4 | 32 | 0.50 x 0.38 x 0.38 x 0.33 m | 4 | 128 |

| H-144(Hot sale) | 2.15 x 2.1 x 1.2 m | 2 | 16 | 0.43 x 0.38 x 0.38 x 0.33 m | 9 | 144 |

| H-192 | 1.88 x 2.4 x 1.8 m | 4 | 32 | 0.47 x 0.35 x 0.37 x 0.32 m | 6 | 192 |

| H-240 | 2.0 x 2.4 x 1.8m | 4 | 40 | 0.50 x 0.38 x 0.38 x 0.33 m | 6 | 240 |

| Material | Mild steel Q235; | |||||

| Surface Treatment and Service Life | Electro galvanized, Zinc coating ≤ 8 g/m2, (7-10 years); Hot-dip galvanized, Zinc coating: ≤ 275 g/m2, (15-20 years); Notes: The service life depends on the surrounding environment. | |||||

Advantages of Layer Chicken Cage

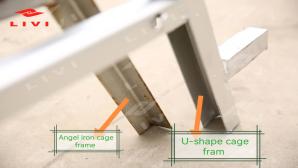

Frame

- U shape, 2 mm thickness 3 sides, cold roll forming no welding part stronger

- 275gsm Zinc coating the same metal sheet as the battery cage

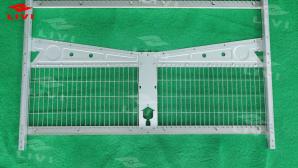

Smooth Mesh Surface

- LIVI upgraded hot dipped galvanized process, smooth surface

- Not hurt chicken feet

Strong Cage Mesh

- Q235 wire, yield strength N>600, not easy to bend

- 3mm reinforcing wire to hang the cage

Cage Floor Mesh Connector

- LIVI upgraded cage, with metal connector

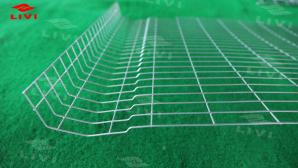

Cage Floor Mesh

- Add one wire, no gap, and reduce broken eggs

Strong Cage Floor Mesh

- All the warp wire (the long wire) is 3mm, reinforcing wire, preventing bending

Customized Solutions – Reach Out Now!

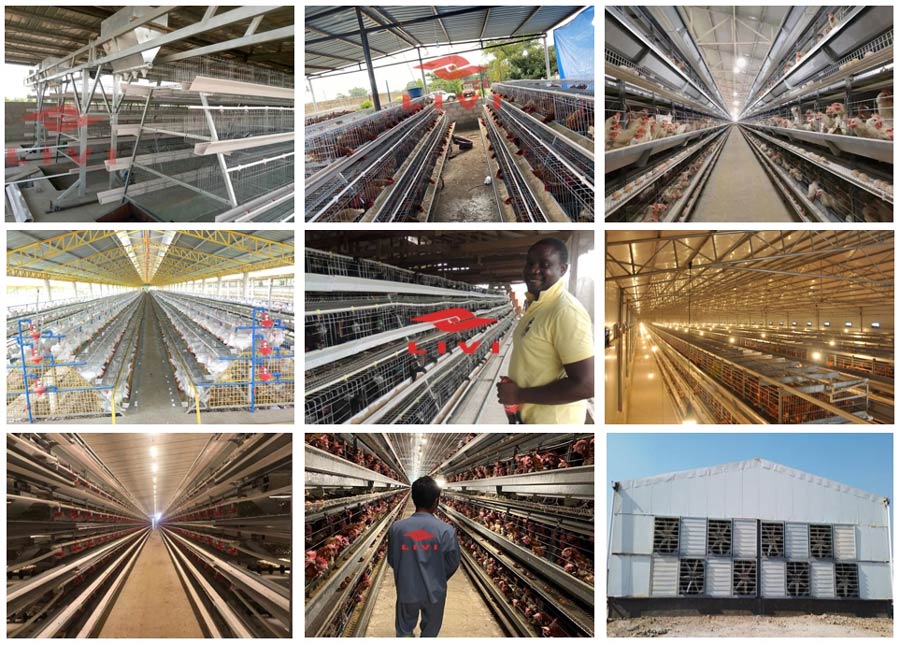

Turnkey Poultry Solutions in Nigeria

To get more service details please contact us.

Feed Egg Ratio: 2.0:1

Eggs Broken Rate: <0.3%

Max Quantity: 100000/House

More Professional Design

Combined with European Technology